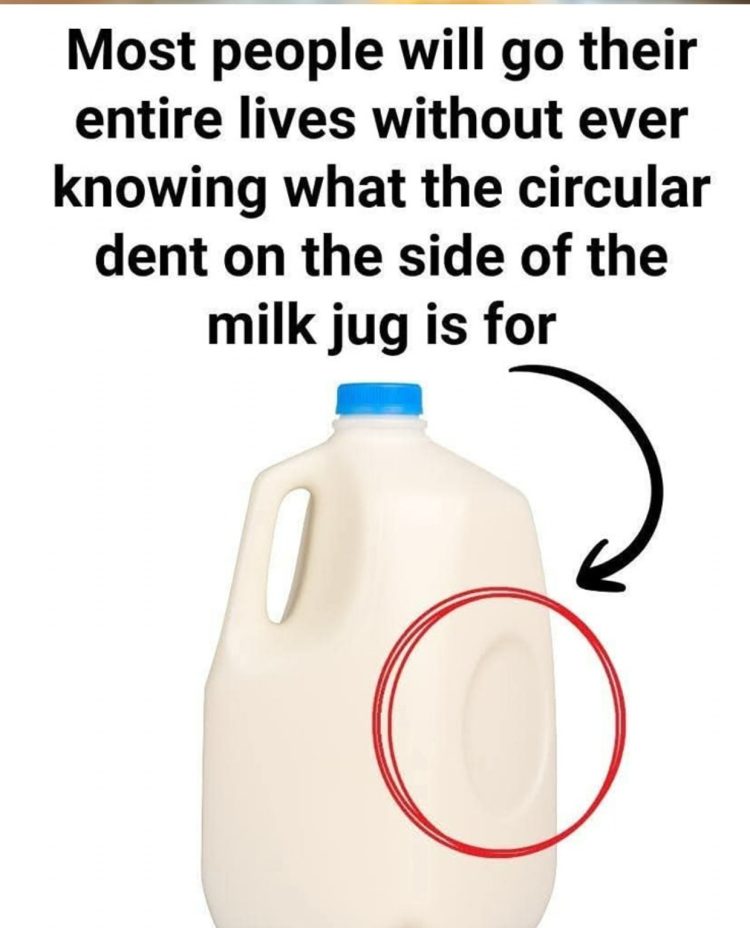

You’ve seen it a thousand times—that mysterious circular dent on the side of plastic milk jugs. But have you ever wondered why it’s there?

Turns out, it’s not just a random design quirk. That little indentation actually serves three genius purposes—and once you know them, you’ll never look at milk cartons the same way again!

1. Structural Stability: Preventing the “Milk Jug Bulge”

Ever notice how milk jugs don’t balloon out when sealed? That dent is the reason!

✅ Prevents Expansion – When milk is packaged, hot liquid is poured in, then cools and contracts. Without the dent, the jug would warp inward and become unstable.

✅ Reinforces the Jug – The circular shape distributes pressure evenly, keeping the container rigid and preventing leaks or cracks.

2. Safety Feature: A Built-In “Overfill” Indicator

That dent isn’t just for structure—it’s also a clever manufacturing trick!

🔍 How It Works:

-

During filling, milk should just touch the bottom of the dent.

-

If the jug is overfilled, the liquid rises past the circle, alerting workers to adjust the machine.

-

This ensures consistent fill levels and prevents messy spills in transit.

3. Stacking & Shipping Efficiency

Milk jugs are designed for maximum storage efficiency, and that dent plays a key role!

📦 Nestable Design – The indentation allows jugs to fit snugly against each other when stacked in crates or store coolers.

🚛 Prevents Shifting – The slight gap created by the dent reduces friction, making it easier to load and unload pallets without tipping.